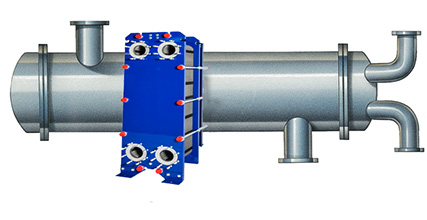

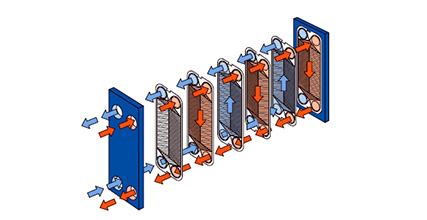

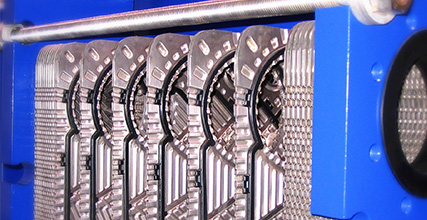

A plate and frame heat exchanger as known as gasketed plate heat exchanger is a high efficiency heat exchanger that is assembled from a series of metal sheets with a certain corrugated shape. A thin rectangular channel is formed between the various sheets, and heat is exchanged through the sheets.

Principle

A plate and frame heat exchanger as known as gasketed plate heat exchanger is a high efficiency heat exchanger that assembled from metal sheets with corrugated pattern and different kind of gaskets. Plate heat exchangers are the ideal equipment for heat exchange between liquid-liquid and liquid-vapor.In the case of the same pressure loss, the heat transfer coefficient is 3-5 times higher than that of the tube heat exchanger, but the floor space is one-third of the tube heat exchanger, and the heat recovery rate can be as high as 90% or more.

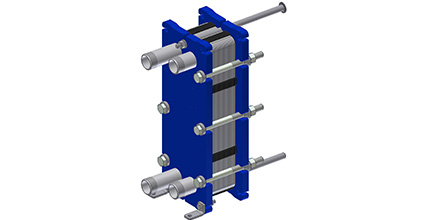

- Maximum volume: 5000m3 /h;Maximum design pressure: 25bar

- Maximum temperature: 200 celsius degree; Minimum difference in temperature: 0.5-1 celsius degree

- Nozzle diameter: DN15~DN500;Plate thickness: 0.4mm - 1.2mm

- Gasket material:NBR, EPDM, HNBR, HT-NBR, HEPDM, CR,VITON/FKM

- Fixed and movable plate material: Carbon Steel, Stainless Steel, and others on request.

- Plate material:AISI304, AISI316, AISI316L, Titanium,Ti-Pa,Hastelloy C276,254SMO,Nickel, AISI904L.

High heat transfer coefficient

High heat transfer coefficient

The design of the plate corrugation is aimed at the high thermal conductivity. The special flow path are formed by the plate corrugation causing strong disturbance flow at a very low flow rate, which is called turbulent flow. And the disturbance flow can be self-cleaning to prevent fouling and thus the heat transfer efficiency is high.

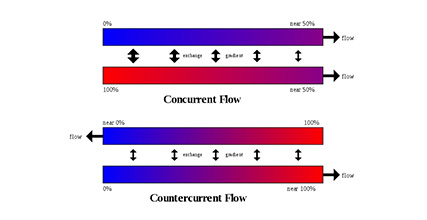

Large logarithmic temperature difference

Large logarithmic temperature difference

The temperature difference at the end is small, and the plate heat exchanger is mostly a cocurrent or countercurrent type of flow. In addition,there's no bypass flow.

Small footprint and easy maintenance

Small footprint and easy maintenance

The plate heat exchanger has a compact structure, and the heat exchange area per unit volume is 2-5 times that of the shell-and-tube type, and the floor area of the plate heat exchanger is about 1/2-1/3 of the shell - tube heat exchanger when achieving same heat exchange capacity .

Easy to change heat transfer area or process combination

Easy to change heat transfer area or process combination

As long as several plates are added or reduced, the purpose of increasing or decreasing the heat exchange area can be achieved. Changing the plate arrangement or replacing several plates can achieve the required path combination to adapt to the new heat exchange conditions.

Low investment

Low investment

With the same heat exchange capacity, when compared with the shell and tube heat exchanger,because of the decrease of heat exchange area, floor space, fluid resistance, cooling water consumption etc, plate heat exchanger has much lower expense on equipment investment, base investment, power consumption etc.

Safe and reliable use

Safe and reliable use

double seal are designed on the sealing device of the plate, and there is a signal slot. Once the leakage occurs, it can be discharged outside the heat exchanger, which prevents the two media from mixing,and at the same time it can be a security alarm.

Selection and design

- 01

Our company has a set-up procedure for the selection and design of the plate heat exchanger. Depending on the specific working conditions provided by the user, the program can make the best solution for this particular condition. And we can provide the calculation data book and heat exchanger dimensional drawing in time. Our company can design and produce heat exchangers according to PED or ASME specifications, and we can provide corresponding factory documents for design, manufacture, inspection, etc. Also we can provide packaging and transportation according to requirements.

- 02

Our plate heat exchangers has passed the approval of relevant Chinese authorities and can be exported to countries all over the world. And we provide technical services and complete relevant documents for our customers.

- 03

Our plate heat exchanger has been applied in many countries around the world, and has been recognized by professional users in various industries. Its application in some industries is unique.

- 04

Our plate heat exchangers can be used in most processes that requiring heat exchange, and can be used in processes such as liquid-liquid, vapor-liquid, condensation, and evaporation.