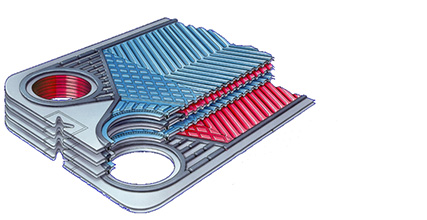

Product principle

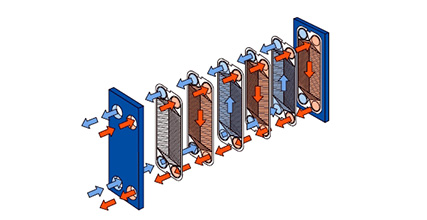

The working principle of the plate evaporator is to compress the secondary steam generated by the equipment through the configured compressor, then raise the pressure and temperature to a certain range, and finally transfer it to the relevant heating chamber of evaporator as heating steam. Finally, to perform the condensation heat release program, so that it can help the latent heat of the steam and the recycling can be effectively obtained.

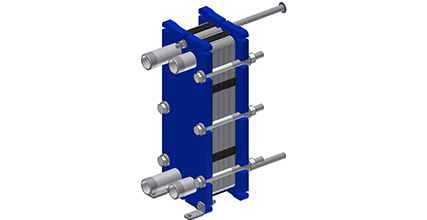

Maximum heat transfer area: 500m2/set; Maximum design pressure:16bar

Maximum temperature:200 celsius degree; Nozzle diameter:DN50~DN500

Plate thickness:0.4mm;Gasket material:NBR, EPDM, HNBR, HT-NBR, HEPDM, CR, VITON/FKM

Fixed and movable plate material: Carbon Steel, Stainless Steel, and others on request.

Plate material:AISI304, AISI316, AISI316L, Titanium, Ti-Pa,Hastelloy C276,254SMO,Nickel, AISI904L.

Advantages

High heat transfer efficiency

High heat transfer efficiency

The plate evaporator is ingenious in design, so the heat transfer efficiency is higher than that of the general evaporator. Generally, the plate evaporator area only needs about one-half of the tube evaporator then can achieve the same evaporation effect.

Compact overall structure

Compact overall structure

The whole structure is compact, floor space is small, and there is no need to invest too much manpower and material resources in the later use process. For some maintenance work, it only needs to be carried out in the original space range, and it's very simple whether it is disassembled or installed .

Diversification of components

Diversification of components

The heat exchange area can be effectively adjusted according to the customer's needs: now the heat exchange area of different evaporators has different ranges, since the heat exchanger plates can be disassembled, so multiple components with multiple skills and more new functions can be provided through adjusting number of plates and changing relative flow path.

Small heat loss

Small heat loss

Because this type of equipment is compact in structure and relatively light in weight, compared with tubular evaporators, it also reduces heat loss, and such equipment usually does not need to be insulated.

Less pressure loss

Less pressure loss

Under the same heat transfer coefficient condition, such evaporator equipment can control the pressure loss within a certain range by rotating a reasonable flow rate.Compared with tubular evaporator,it can reduce 2/3 pressure loss.

Stable and safe operation

Stable and safe operation

Different sealing procedures are designed on the sealing device between the plates, and signal holes are also arranged. Once there is leakage or other malfunction, the safety alarm will work.

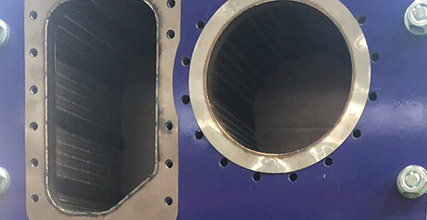

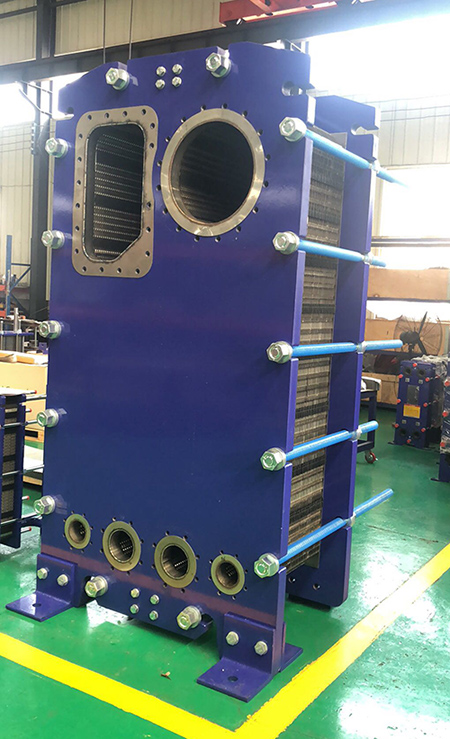

Product Display

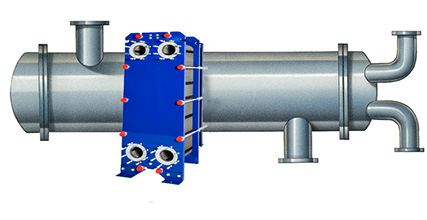

Semi welded plate heat exchanger

Semi welded plate heat exchanger Semi welded plate heat exchanger

Semi welded plate heat exchanger Semi welded plate heat exchanger

Semi welded plate heat exchanger

Range of application

Metallurgy, food industry, paper industry, air conditioning, chemical and desalination industries