food grade Titanium palladium wide gap plate heat exchanger wholesale price

Model No.︰GEA

Brand Name︰reapter

Country of Origin︰China

Unit Price︰CNY ¥ 1000 / pc

Minimum Order︰1 pc

Product Description

Wide Runner (Free Flow) Plate Heat Exchanger

Maximum treatment capacity: 5000 cubic meters/hour

Maximum design pressure: 40 bar

Maximum temperature resistance: 200℃

Minimum temperature difference:0.5-1℃

Tube diameter: DN15~500

Plate thickness: 0.4mm - 1.2mm

Gasket material: NBR, EPDM, HNBR,HT-NBR,HEPDM,CR,VITON/FKM

Plate material: 304, 316, 316L, titanium, titanium palladium, hastelloy C276, 254SMO, nickel, 904L, etc.

Product Features

CHARACTERISTICS

High heat transfer coefficient

01 High heat transfer coefficient

The corrugated shape of the sheet is designed for high thermal conductivity of the film, which forms thin rectangular channels that allow the fluid to flow at low velocities. Strong turbulence can also occur under The turbulence has a self-cleaning effect to prevent the formation of fouling, resulting in a high heat transfer efficiency. In general, the heat transfer coefficient K of the plate heat exchanger is in the range of 3000-8000W/m2℃. This indicates that the plate heat exchanger only needs 1/2-1/4 of the shell and tube heat exchanger area to achieve the same heat transfer effect.

Large mean logarithmic temperature difference

02 Large log-averaged temperature difference

Plate heat exchanger is mostly parallel or counter-current flow mode. Select the number of processes and channels, the initial selection of cold, hot fluid flow and the number of channels, and thus calculated flow rates. Cold, hot fluid in the plate heat exchanger flow parallel to the heat transfer surface, no bypass, thus making the end temperature difference is small, the logarithmic mean temperature difference is large .

Compact structure with small cooling capacity and low investment

03 Compact structure, small cooling water volume, low investment

Plate heat exchanger is an efficient and compact heat transfer equipment, the heat transfer area per unit volume is 2-5 times the shell and tube type. Small footprint, easy to maintain and clean, to achieve the same heat transfer, plate heat exchanger covers an area of about 1/5 of the shell and tube heat exchanger ~The geometric shape of the runner allows for high heat transfer efficiency of the liquid, which greatly reduces water consumption for cooling and is economical.

Easy to expand, change the heat transfer area or process combination

04 Easy to expand, change the heat transfer area or process combination

As long as the increase or decrease a few plates, you can achieve the purpose of increasing or reducing the heat transfer area; change the plate arrangement or replacement of several plates, you can achieve the required combination of processes to adapt to the new heat transfer conditions, while the shell and tube heat exchanger heat transfer area is almost impossible to increase.

Not easy to build up scale, easy to clean, safe and reliable

05 Not easy to build up scale, easy to clean, safe and reliable

Smooth heat exchanger surface, large turbulence, full flow of internal media, impurities are not easily deposited and scaling, small dead flow area in the channel between plates; only frame The plate heat exchanger can be loosened by loosening the clamping bolts, and the plate can be removed for mechanical cleaning, which is important for frequent cleaning of the equipment. The heat transfer process is very convenient. The plate seal is designed with two seals and a signal slot to allow it to be discharged outside the heat exchanger in the event of a leak. It prevents the two media from mixing and also serves as a safety alarm.

Heat loss, and low drag loss

06 heat loss, and low drag loss

Only the housing of the heat transfer plate is exposed to the atmosphere, so heat loss is negligible and insulation is not required. The shell and tube heat exchanger has large heat loss and needs thermal insulation layer; under the same heat transfer coefficient condition, through the reasonable multi-process combination arrangement, the more The process combination exhibits a mixed flow pattern with a slightly lower average heat transfer temperature difference. Resistance losses can be controlled within 1/3 of the shell and tube heat exchanger range.

Products

PRODUCT DISPLAY

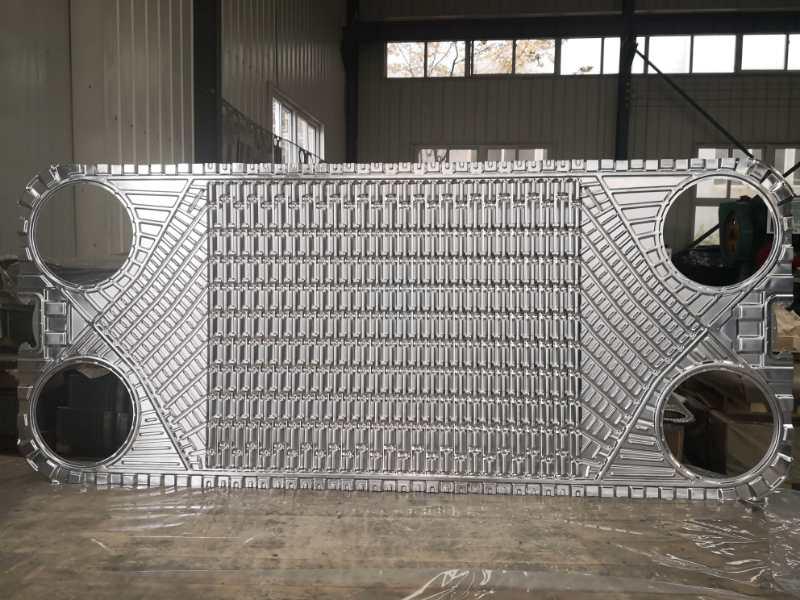

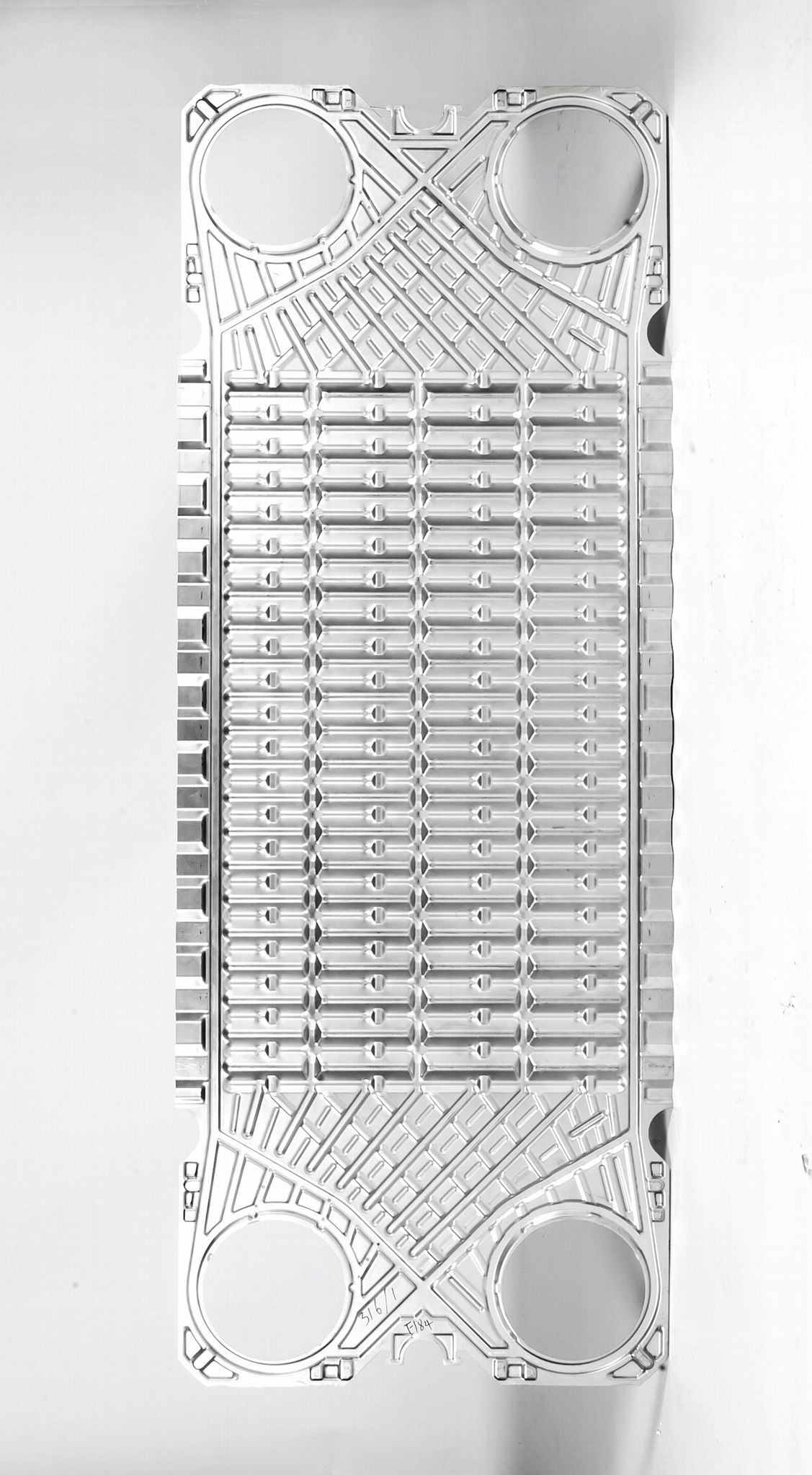

Plate heat exchanger-ATS150M/B

Wide Runner Plate Heat Exchanger - N40

Plate heat exchanger-AT100M/B

Wide Runner Plate Heat Exchanger-MA30S

Plate heat exchanger-AT150M/B

Wide Runner Plate Heat Exchanger - SF160

Selection design

LECTOTYPE DESIGN

01Rapid heat exchanger manufacturers have experienced scientific research and technical team, can propose solutions based on the customer's specific working conditions, and provide timely calculations data book and heat exchanger dimensional drawings.

02 RepuTex plate heat exchanger has passed all the approvals from the relevant authorities in China and can be exported to all countries in the world to provide technical service and related documents for customers.

03 Rippert plate heat exchanger has been used in many countries around the world and is recognized by users in a number of industries.

04 Rippert plate heat exchanger can be used for most processes that require heat exchange, and can be used for liquid-liquid, vapor-liquid, condensation, evaporation, heat recovery and other processes.

Areas covered

AREAS INVOLVED

The areas covered are: oil industry; heating and ventilation area; electrical energy; food and pharmaceutical industry; iron and steel industry; machine building industry; chemical industry; textile industry; automobile industry, etc.

Payment Terms︰ TT

Product Image